From the consultation on the constructional design and the tool making through to the serial production and component assembly

This holistic concept enables the system partner to produce sophisticated and complex thermoplastic injection molded parts

Our in-house expertise ensures short reaction times and the highest quality right from the start.

The highlights include:

Design

The business section Plastics Processing serves the customers as from the initial idea through to the finished product:

- Technical contact persons with a high level of expertise

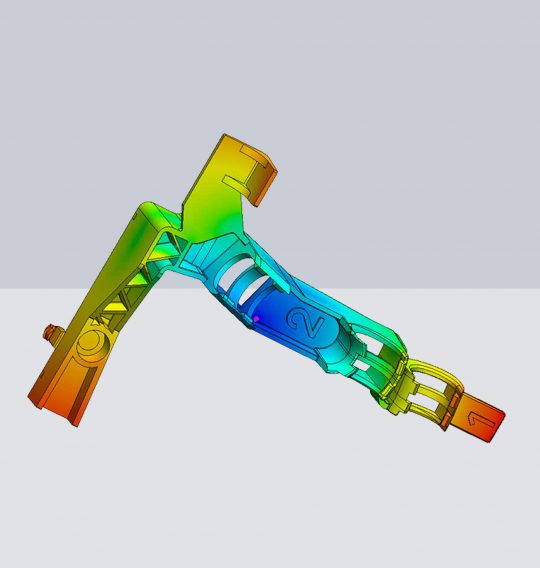

- Design with SolidWorks (parts and tools)

- Simulation with SolidWorks Plastics on filling behaviour, warpage and cooling calculation

- Rigorous project management with international partners

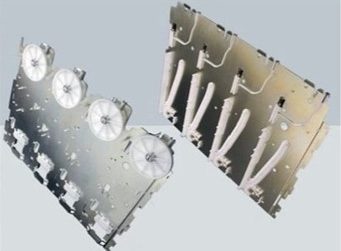

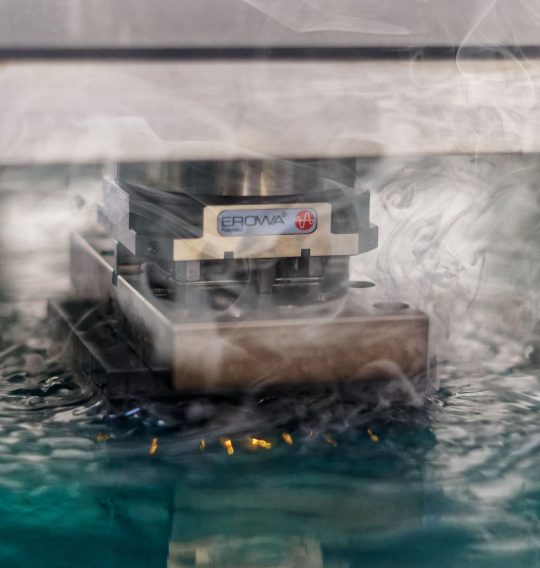

Tool making

The company's own qualified toolmaking is one of the guarantors for the successful realization of even complex projects.

- 5-axis milling machine

- CAD / CAM stations

- Milling and laser machines

- Erosion technology

- CNC lathes

- Long automatic lathes

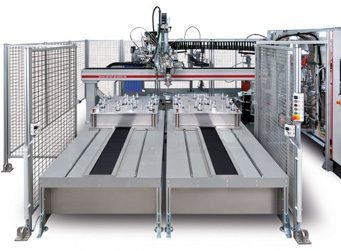

Production

Thermoplastic injection molded parts are produced with the highest precision for a wide variety of applications:

- Components up to a part weight of 30 kg

- Closing force range 28 to 2,300 t

- Complex automation solutions

- Central material supply

- Diverse special techniques

- Component assembly

Quality assurance

Decades of experience and know-how make the BMF Kunststoff-System-Technik GmbH a reliable partner in plastics processing.

- 3D laser scanner

- 3D coordinate measuring machine

- 2-flank rolling tester (gear wheels)

- Laser concentricity gauge (axles, shafts)

- Colorimeters

- MFI / MVI devices

- UL certification

We are at your disposal as from the initial idea through the design and the toolmaking up to the serial and component production.